busch vacuum pump manual

Busch Vacuum Pump Manual: A Comprehensive Guide

Busch vacuum pumps deliver efficiency and reliability, with the R5 series offering rapid oil changes—reducing maintenance costs by 40%.

These pumps, rooted in 1960s rotary vane technology, serve diverse industries, from labs to food processing, ensuring consistent performance.

Busch Vacuum Pumps and Systems stands as a global leader in the creation of vacuum technology, renowned for both innovation and dependability. For decades, Busch has consistently delivered solutions tailored to a vast spectrum of industrial applications, ranging from laboratory settings and medical technologies to food processing, chemical manufacturing, and packaging.

The company’s commitment to engineering excellence is evident in its diverse product portfolio, encompassing rotary vane pumps, screw pumps, diaphragm pumps, and customized vacuum systems. A cornerstone of Busch’s success lies in its pioneering rotary vane design, which revolutionized packaging lines in the 1960s, offering a reliable alternative to previously available technologies.

Today, Busch continues to push boundaries, focusing on energy efficiency, reduced maintenance requirements, and environmentally responsible operation. This manual serves as a comprehensive resource for understanding, operating, and maintaining Busch vacuum pumps, ensuring optimal performance and longevity.

Understanding Rotary Vane Technology

Rotary vane technology, central to many Busch vacuum pumps, operates on a remarkably simple yet effective principle. An eccentrically mounted rotor spins within a cylindrical housing. As the rotor turns, spring-loaded vanes slide in and out, creating chambers of varying volume.

During the intake stroke, these expanding chambers draw in gas. As the chambers decrease in volume on the exhaust side, the gas is compressed and discharged. Crucially, a film of oil seals the vanes against the housing, ensuring a tight seal and efficient pumping action.

This oil sealing is fundamental to the technology’s reliability and performance. It minimizes leakage, handles liquids effectively, and contributes to the pump’s ability to achieve deep vacuum levels. Busch’s refinement of this core concept, particularly in the R5 series, has resulted in pumps known for their durability and low maintenance needs.

The R5 Series: Key Features and Benefits

The Busch R5 rotary vane series represents a cornerstone of reliable vacuum technology, widely utilized across diverse applications. A primary benefit lies in its exceptionally quick oil change capability – completing a full oil change in under five minutes without requiring specialized tools. This dramatically reduces annual maintenance expenditures, estimated at around 40% savings.

Further enhancing serviceability, many R5 models incorporate transparent oil sight glasses, allowing for immediate visual inspection of oil condition. Complementing this are magnetic drain plugs, capturing metallic particles and extending service intervals.

The R5 series, including models like the R5 RA 0165-0305, is specifically designed for rough vacuum applications, guaranteeing clean exhaust even under demanding conditions. This combination of efficiency, ease of maintenance, and robust design makes the R5 series a compelling choice.

Rapid Oil Change Capabilities

A defining characteristic of the Busch R5 series is its remarkably swift oil change process. Unlike traditional vacuum pumps requiring extensive time and specialized tools, the R5 allows for complete oil changes to be executed in under five minutes. This streamlined procedure significantly minimizes downtime and associated labor costs, contributing to substantial operational savings.

The simplicity of the oil change process is a key advantage, reducing the need for highly trained technicians and complex procedures. This accessibility empowers maintenance personnel to perform routine oil changes efficiently, maintaining optimal pump performance.

This rapid oil change capability directly translates to approximately a 40% reduction in annual maintenance costs, making the R5 series a financially prudent investment for businesses prioritizing efficiency and cost-effectiveness.

Simplified Maintenance with Sight Glasses & Drain Plugs

Busch vacuum pumps, particularly within the R5 series, are engineered for ease of maintenance, incorporating features like transparent oil sight glasses and magnetic drain plugs. These components dramatically simplify routine inspections, allowing technicians to quickly assess oil levels and identify potential contaminants without disassembly.

The strategically placed sight glasses provide a clear visual indication of oil condition, enabling proactive maintenance and preventing unexpected failures. Furthermore, the magnetic drain plugs capture metallic particles, safeguarding critical pump components from wear and tear and extending service intervals;

These thoughtful design elements minimize downtime and reduce the need for extensive maintenance procedures, ultimately contributing to increased operational efficiency and reduced lifecycle costs. Regular inspection facilitated by these features ensures optimal pump performance and longevity.

Busch Cobra Series Screw Vacuum Pumps

Busch’s Cobra series screw vacuum pumps represent a significant advancement in vacuum technology, designed for demanding applications requiring high performance and reliability. The COBRA BC 0100 F series, in particular, integrates Programmable Logic Controller (PLC) controls for precise operation and monitoring, enhancing automation capabilities.

A key feature of the Cobra series is its specialized coating, engineered to withstand corrosive gases and vapors, making them ideal for chemical processing and similar environments. These pumps utilize a direct cooling method, ensuring uniform temperature distribution throughout the pump body, which minimizes thermal stress and maximizes operational lifespan.

This consistent temperature control contributes to stable performance and reduced maintenance needs. The Cobra series delivers robust vacuum performance and durability, making them a preferred choice for critical industrial processes.

PLC Controls and Corrosive Gas Handling

Busch Cobra screw vacuum pumps demonstrate advanced control through integrated Programmable Logic Controllers (PLC). These PLC systems enable precise monitoring and adjustment of pump parameters, optimizing performance for specific applications and facilitating seamless integration into automated processes.

Beyond control, the COBRA BC 0100 F series is specifically engineered for handling corrosive gases and vapors. A specialized coating protects internal components from chemical attack, ensuring longevity and reliability in harsh environments. This capability is crucial for industries like chemical processing, where exposure to aggressive substances is common.

The combination of PLC control and corrosion resistance makes these pumps a versatile and dependable solution, minimizing downtime and maximizing efficiency in challenging industrial settings.

Direct Cooling for Temperature Uniformity

Busch Cobra series screw vacuum pumps utilize a sophisticated direct cooling method, a key feature in maintaining optimal operational temperatures. Unlike traditional cooling systems, direct cooling ensures a remarkably uniform temperature distribution throughout the entire pump body.

This consistent temperature profile is critical for several reasons. It minimizes thermal stress on components, extending their lifespan and reducing the risk of failure. Furthermore, uniform temperature enhances pumping efficiency and maintains stable performance even under demanding workloads.

By preventing localized hotspots, direct cooling contributes to the overall reliability and longevity of the Cobra pumps, making them ideal for continuous operation in industrial applications where consistent performance is paramount.

Applications of Busch Vacuum Pumps

Busch vacuum pumps demonstrate remarkable versatility, serving a broad spectrum of industries and applications. From the foundational role in revolutionizing packaging lines in the 1960s, their technology has expanded significantly.

Today, Busch pumps are integral to laboratory processes, ensuring precise and reliable vacuum environments for research and analysis. The food processing industry relies on them for modified atmosphere packaging, extending shelf life and preserving product quality.

Furthermore, Busch pumps are crucial in chemical industries, handling various gases and vapors with efficiency and safety. They also excel in rough vacuum sector applications, providing robust performance for diverse industrial needs. Their adaptability makes them a preferred choice across numerous sectors.

Rough Vacuum Sector Applications

Busch vacuum pumps, particularly the R5 RA 0165 ⸺ 0305 models, are specifically engineered for applications within the rough vacuum sector. These pumps excel in processes requiring moderate vacuum levels, offering a cost-effective and reliable solution for various industrial needs.

Common applications include pneumatic conveying systems, where vacuum is used to transport materials. They are also vital in central vacuum systems for manufacturing facilities, providing efficient dust and debris removal. Furthermore, Busch pumps support clamping and lifting applications, ensuring secure handling of materials.

The optimized internal oil separation within these models guarantees clean exhaust, even under demanding conditions. This makes them suitable for processes where environmental considerations are paramount, delivering both performance and responsible operation.

Energy Efficiency in Busch Pump Design

Busch Vacuum Pumps and Systems consistently responds to the demand for maximum energy efficiency in vacuum technology. Their designs prioritize minimizing energy consumption without compromising performance, resulting in lower operating costs and a reduced environmental footprint.

This commitment is reflected in optimized pump geometries and advanced sealing technologies, reducing leakage and maximizing pumping speed. Efficient motor designs and intelligent control systems further contribute to energy savings, adapting pump performance to actual process requirements.

By focusing on these aspects, Busch pumps deliver substantial energy reductions compared to older technologies. This not only benefits the user’s bottom line but also supports sustainability goals, aligning with a growing emphasis on responsible industrial practices.

Lubricated Rotary Vane Pump Models (R5 RA Series)

The R5 RA Series represents a cornerstone of Busch’s rotary vane pump offerings, specifically engineered for rough vacuum applications. These pumps are renowned for their robust construction and reliable performance across a wide range of industrial processes.

Within this series, the R5 RA 0165 ⸺ 0305 models stand out, offering optimized internal oil separation to guarantee clean exhaust, even under demanding conditions. This feature is crucial for maintaining product quality and environmental compliance.

The R5 RA 0205 F model, in particular, is a 1.5 HP unit designed for specific applications requiring a balance of performance and efficiency. These pumps benefit from the proven rotary vane design that revolutionized packaging lines decades ago, continuing to deliver dependable operation today.

R5 RA 0165 ⸺ 0305 Models

The R5 RA 0165 through 0305 models are integral to Busch’s commitment to reliable rough vacuum solutions. These pumps are specifically designed for applications demanding consistent performance and durability within the rough vacuum sector. A key characteristic is their optimized internal oil separation system.

This advanced oil separation guarantees exceptionally clean exhaust, a critical factor for processes sensitive to contamination. This feature ensures adherence to stringent environmental standards and maintains product integrity. The design prioritizes ease of maintenance and extended service intervals.

These models represent a continuation of Busch’s legacy of innovation, building upon the foundational rotary vane technology that transformed industries in the 1960s. They are a testament to the enduring power of simple, yet effective, engineering principles.

R5 RA 0205 F Model Specifications

The R5 RA 0205 F is a lubricated rotary vane vacuum pump, boasting a 1.5 HP motor, designed for robust performance in various applications. This model belongs to the well-established R5 family, known for its reliability and efficiency. It’s particularly suited for rough vacuum applications where consistent suction power is essential.

Key specifications include its ability to handle a wide range of gases and vapors, making it versatile for diverse industrial processes. The ‘F’ designation often indicates specific features tailored for particular applications, potentially including enhanced filtration or materials compatibility.

This pump benefits from Busch’s commitment to user-friendly design, incorporating features like simplified oil changes and readily accessible maintenance points. It represents a balance of power, efficiency, and ease of service, embodying the core principles of Busch vacuum technology.

Oil Separation Technology

Busch vacuum pumps utilize advanced oil separation technology to ensure clean exhaust and minimize environmental impact. This crucial feature prevents oil mist and vapor from being released into the atmosphere, complying with stringent emission standards and protecting downstream processes.

The R5 RA 0165 ― 0305 models, in particular, feature optimized internal oil separation, guaranteeing clean exhaust even under demanding conditions. This is achieved through a multi-stage separation process, effectively removing oil droplets and aerosols from the exhaust stream.

Effective oil separation not only benefits the environment but also extends the lifespan of the pump and reduces maintenance requirements. By preventing oil buildup in the system, it maintains optimal performance and minimizes the risk of component failure, showcasing Busch’s dedication to longevity and efficiency.

Exhaust Gas Management

Busch vacuum pump systems prioritize responsible exhaust gas management, recognizing the importance of environmental protection and workplace safety; Effective handling of exhaust gases is crucial, especially when dealing with corrosive or hazardous substances.

The Cobra BC 0100 F series exemplifies this commitment, featuring a special coating designed for handling corrosive gases and vapors; This protective layer prevents damage to the pump components and ensures reliable operation in challenging environments.

Furthermore, Busch pumps, through optimized oil separation, minimize oil carryover into the exhaust stream, contributing to cleaner emissions. Proper exhaust gas management also involves appropriate filtration and venting systems, tailored to the specific application and regulatory requirements, demonstrating Busch’s holistic approach to vacuum technology.

Maintenance and Troubleshooting

Busch vacuum pumps are engineered for durability, but regular maintenance is vital for optimal performance and longevity. Simplified maintenance features, like transparent oil sight glasses and magnetic drain plugs found in the R5 series, facilitate routine inspections and extend service intervals.

Rapid oil change capabilities – completing a full change in under 5 minutes without specialized tools – significantly reduce downtime and associated costs. Troubleshooting often involves checking oil levels, inspecting for leaks, and verifying proper operation of cooling systems.

Consulting the detailed Busch vacuum pump manual is crucial for identifying specific error codes and recommended corrective actions. Proactive maintenance, coupled with prompt troubleshooting, ensures continued reliability and minimizes unexpected disruptions to your operations.

Extending Service Intervals

Busch vacuum pump design prioritizes longevity and reduced maintenance demands. Utilizing optimized internal oil separation technology, particularly in models like the R5 RA series, contributes significantly to extending service intervals and maintaining clean exhaust emissions.

Regularly monitoring oil condition via the integrated sight glasses allows for informed decisions regarding oil changes, preventing premature replacements. Magnetic drain plugs capture metallic particles, safeguarding internal components and minimizing wear.

Adhering to the recommended maintenance schedule outlined in the Busch vacuum pump manual, coupled with consistent monitoring of pump performance, is key to maximizing uptime. Proactive care translates to fewer interruptions and a lower total cost of ownership.

Historical Development of Busch Vacuum Technology

Busch’s legacy in vacuum technology began to solidify in the 1960s with the introduction of their innovative rotary vane design. This breakthrough revolutionized packaging lines, offering a level of reliability previously unattainable with competing technologies.

The core principle of oil-sealed operation, though simple, proved remarkably robust and efficient. This foundational engineering concept has been continuously refined and adapted over the decades, forming the basis for Busch’s current range of vacuum pumps.

From its initial impact on packaging, Busch technology expanded to serve diverse sectors, including laboratories, food processing, and chemical industries. This evolution demonstrates a commitment to innovation and a deep understanding of evolving industrial needs.

The 1960s: Revolutionizing Packaging Lines

The 1960s marked a pivotal era for Busch, as the introduction of their rotary vane vacuum pump fundamentally altered packaging processes. Prior to this innovation, packaging lines frequently suffered from inconsistencies and failures due to the limitations of existing vacuum technology.

Busch’s oil-sealed rotary vane design offered a significant leap forward in reliability and performance. This simple, yet powerful, principle provided a consistent vacuum, leading to improved packaging integrity and reduced product spoilage.

The impact was immediate and widespread, quickly establishing Busch as a leading provider of vacuum solutions for the packaging industry. This success laid the groundwork for future expansion into other sectors, solidifying Busch’s position as a global leader in vacuum technology.

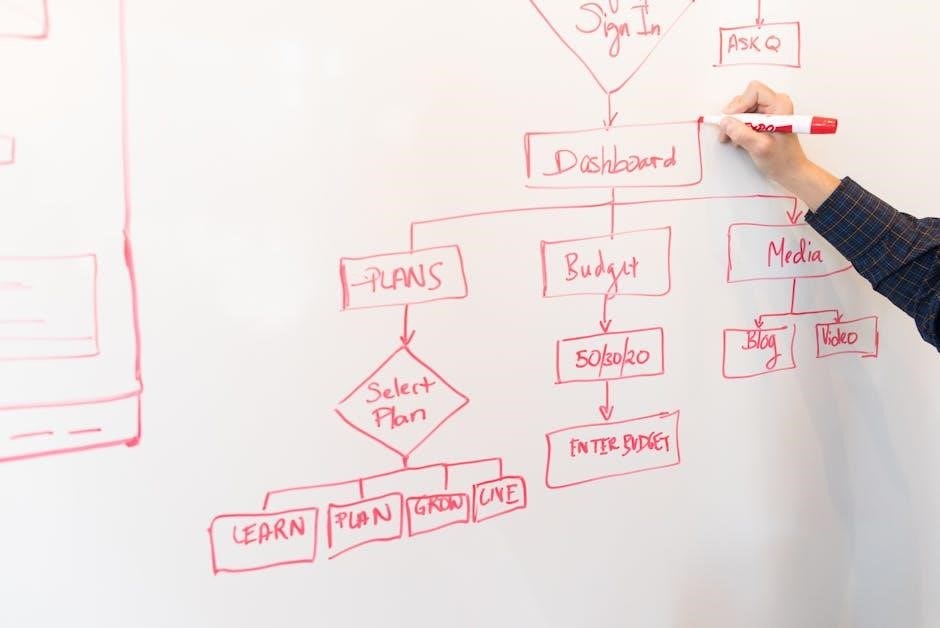

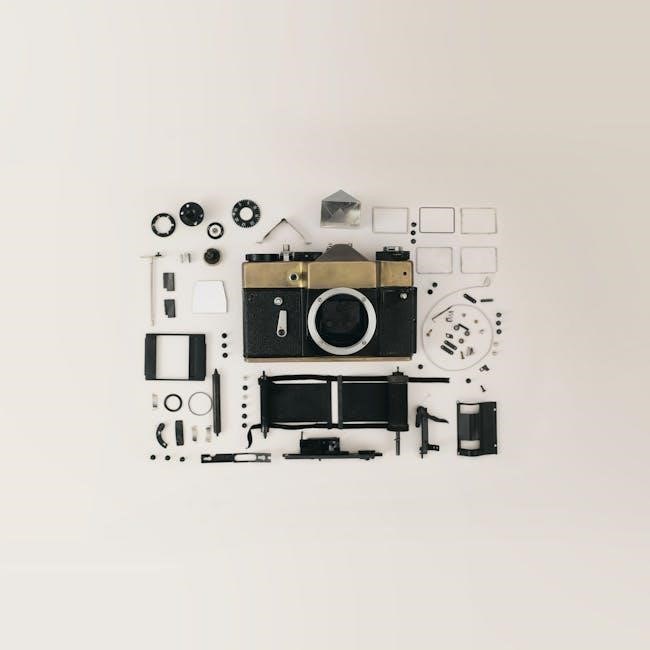

Busch Pump Components Overview

Busch vacuum pumps, particularly the R5 series, are comprised of several key components working in harmony to deliver reliable performance. Central to operation is the rotary vane, which creates the vacuum through a cyclical process of expansion and contraction within the pump housing.

Effective oil separation is crucial, and Busch employs optimized internal systems to ensure clean exhaust, even under demanding conditions. Magnetic drain plugs and transparent sight glasses facilitate easy monitoring of oil levels and condition, simplifying routine maintenance.

The Cobra series incorporates PLC controls for precise operation and specialized coatings for handling corrosive gases. Direct cooling systems maintain uniform temperatures, enhancing longevity and efficiency. These components, combined with robust construction, define Busch’s commitment to quality.

Selecting the Right Busch Vacuum Pump

Choosing the optimal Busch vacuum pump requires careful consideration of your application’s specific needs. The R5 series, ideal for rough vacuum applications, offers models like the R5 RA 0165-0305, designed for reliability and efficiency.

If corrosive gases are present, the Cobra BC 0100 F series, with its specialized coatings and PLC controls, is a superior choice. Consider the required pumping speed and ultimate vacuum level.

Energy efficiency is a key factor; Busch designs prioritize minimizing energy consumption. Evaluate maintenance requirements – the R5 series’ rapid oil change capability significantly reduces downtime. Consulting with a Busch specialist ensures you select a pump perfectly tailored to your process, maximizing performance and longevity.

Future Trends in Busch Vacuum Pump Technology

Busch continues to innovate, focusing on enhanced energy efficiency and intelligent pump integration. Expect further advancements in oil separation technology, minimizing oil carryover and reducing environmental impact.

The integration of PLC controls, as seen in the Cobra series, will become more prevalent, enabling predictive maintenance and remote monitoring. Development will likely center on pumps capable of handling an even wider range of corrosive gases and vapors.

Furthermore, expect to see pumps designed for increasingly demanding applications, such as advanced packaging and semiconductor manufacturing. Busch’s commitment to sustainability will drive the development of pumps with lower lifecycle costs and reduced carbon footprints, building upon their legacy of reliable vacuum solutions.